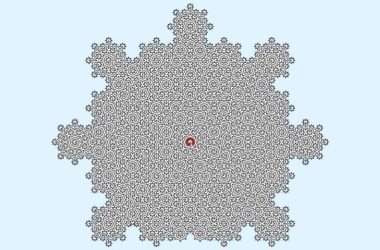

A person with a prosthetic proper eye, which was not created through the AI method

Stephen Bell, Ocupeye Ltd.

Prosthetic eyes which can be designed by synthetic intelligence and 3D printed require 80 per cent much less time from human specialists in contrast with conventional manufacturing strategies, doubtlessly permitting many extra individuals to profit. A small trial additionally means that this method results in well-fitting prosthetics usually.

Within the UK, for instance, around 1 in 1000 people wear prosthetic eyes, which require extremely educated ocularists to take moulds of the attention socket. Many individuals with such prosthetics even have an orbital implant to interchange misplaced eye quantity and create a floor to which muscle groups will be reattached, permitting pure eye motion. Prosthetics sit on high of this to offer a pure look.

The usual course of of constructing a prosthetic takes round 8 hours, however now, Johann Reinhard on the Fraunhofer Institute for Laptop Graphics Analysis in Darmstadt, Germany, and his colleagues have developed a technique that mechanically designs and 3D prints an implant to each match the wearer’s eye socket and aesthetically match any remaining eye.

“It’s extra snug to have an optical scan than having somebody pouring this alginate [mould-making material] impression into your eye socket, notably for kids – it appears to be tough to get them to [sit through] this process,” says Reinhard.

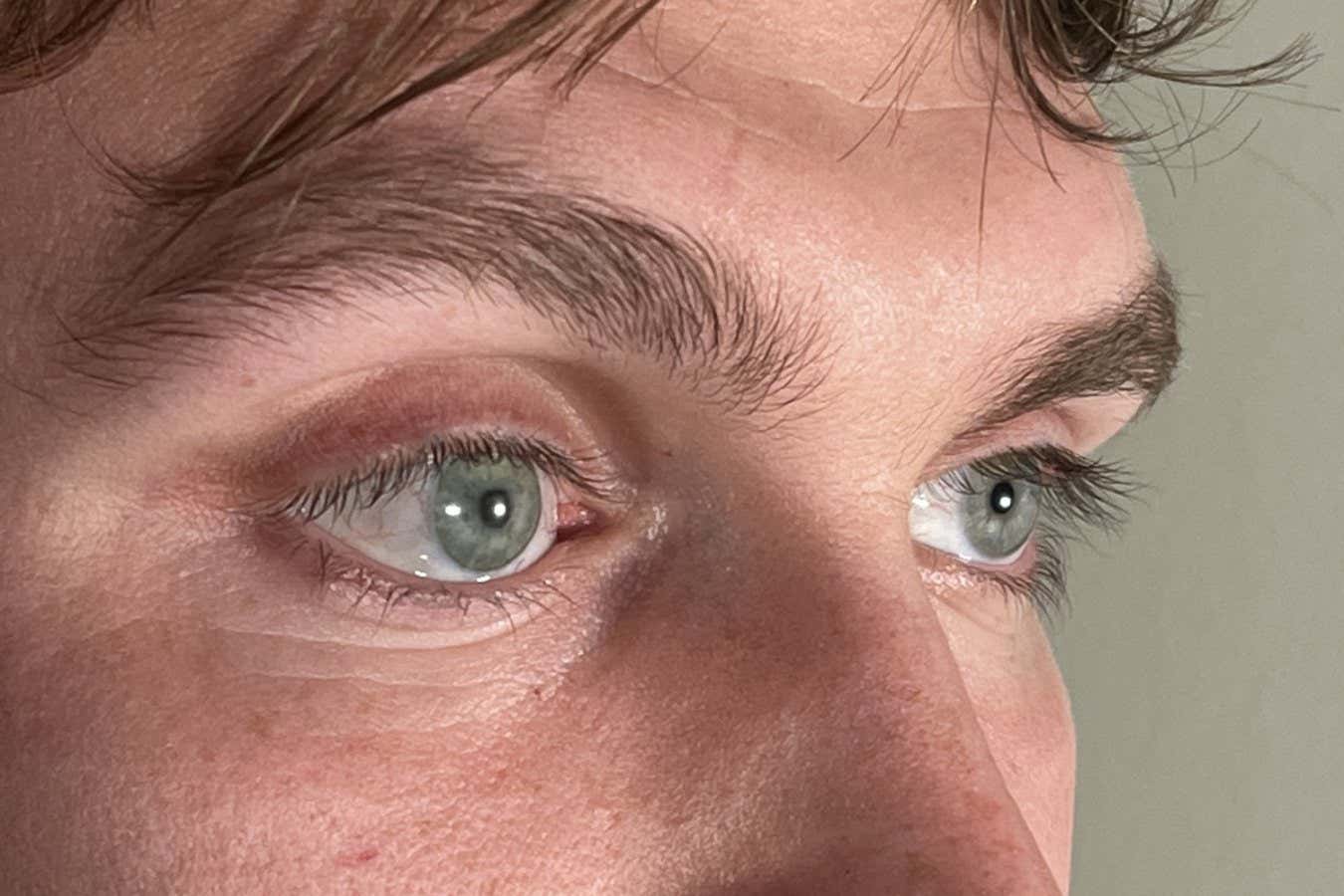

Within the new course of, an optical coherence tomography scanner makes use of gentle to create a 3D mannequin of an individual’s lacking eye, so the again of the prosthetic will be designed for a detailed match. A color picture can be taken of any remaining eye to make an aesthetic match.

The information is funnelled to an AI mannequin, which then creates a design that’s 3D printed by a machine that may function at a decision of 18 billion droplets per cubic centimetre.

As soon as the prosthetic is printed, it may be polished and adjusted to be an ideal match by a human ocularist, a job that takes simply 20 per cent of the time of the prevailing course of.

A 3D-printed eye prosthetic designed by AI

Johann Reinhard, Fraunhofer IGD

In a trial of 10 individuals at Moorfields Eye Hospital in London, there have been solely two individuals for whom these prosthetics didn’t match correctly. Neither had an orbital implant, which Reinhard says is problematic for the scanner and the AI designer.

The group hopes the method will be refined to drastically scale back the price required to create convincing prosthetics and make them accessible to extra individuals. However Reinhard says it’s unlikely that future prosthetics will likely be made with out human specialists in any respect.

“We see this like a instrument for ocularists,” he says. “So it’s not one thing that’s meant to interchange ocularists, but it surely’s a brand new course of that they’ll use and we predict that it supplies higher output by way of look.”

Matters: